The Sintered Metal Filter SMF®

The basic technology of all exhaust treatment systems of HJS is the sintered metal filter (SMF®). This closed filter for buses reduces particulate emissions, including ultra fine particles, by almost 100 percent. HJS has the right system for your needs as it covers all the famous brands such as Mercedes-Benz, MAN, DAF, IVECO, Setra etc..

The suitable system for your requirements

Long distances: SMF-CRT®

The most appropriate system for the long haul - that trucks used primarily for long distance / international transportation on highways - is the proven solution SMF® (sintered metal filter). To use the SMF®, temperatures of exhaust gases must be between 250 °C and 450 °C in the muffler. This temperature range is necessary for the passive regeneration of the filter and is generally accomplished when a truck is used in such transfers.

Small / Medium distance: CSMF-CRT®

The system that is recommended for vehicles that spend most of their time in urban traffic environments is the CSMF® (coated sintered metal filter). The temperature range between 250 °C and 450 °C required for passive regeneration of the filter is rarely achieved under these operating conditions, because the average gas temperature of these vehicles is lower. To improve the regeneration ability, the system CSMF® is equipped with a special catalytic coat.

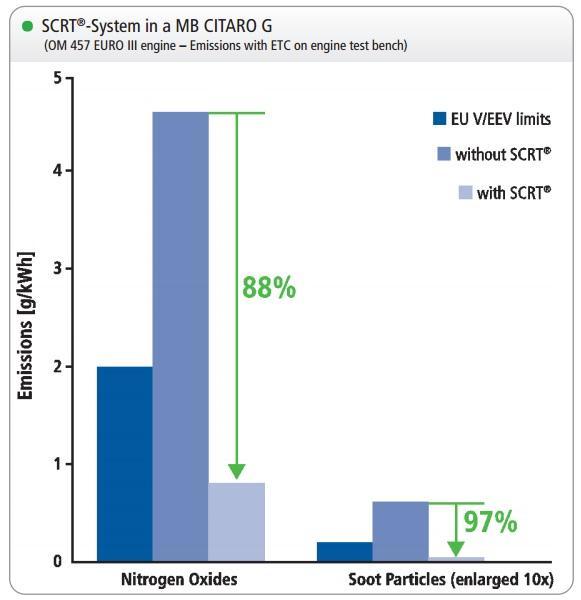

SCRT® system for Buses

The soot resulting from the diesel engines is filtered almost 100% by means of the HJS sintered metal filter. However, the combustion products of diesel engines are also other contaminants that are dangerous to the environment and for our health. Basic such pollutants are nitrogen oxides (NOx). In order to achieve the reduction of these oxides, HJS has developed the system SCRT® (Selective Catalytic Reduction Technology).

The SCRT® combines a particulate filter with a unit SCR® (Selective Catalytic Reduction) that controls the nitrogen oxides. New buses that already have installed particulate filter can be retrofitted with a unit SCR® creating a system SCRT®. Similarly, buses that do not have exhaust management system can be retrofitted with a SCRT® system and converted to vehicles that meet the requirements of Euro V standard for emissions.

Quick and easy installation

The portions of SMF® are mounted in a stainless steel casing with the same dimensions as the original muffler. This means that it can easily be fitted into the existing exhaust system of any truck without the need to modify the compounds.

Maintenance

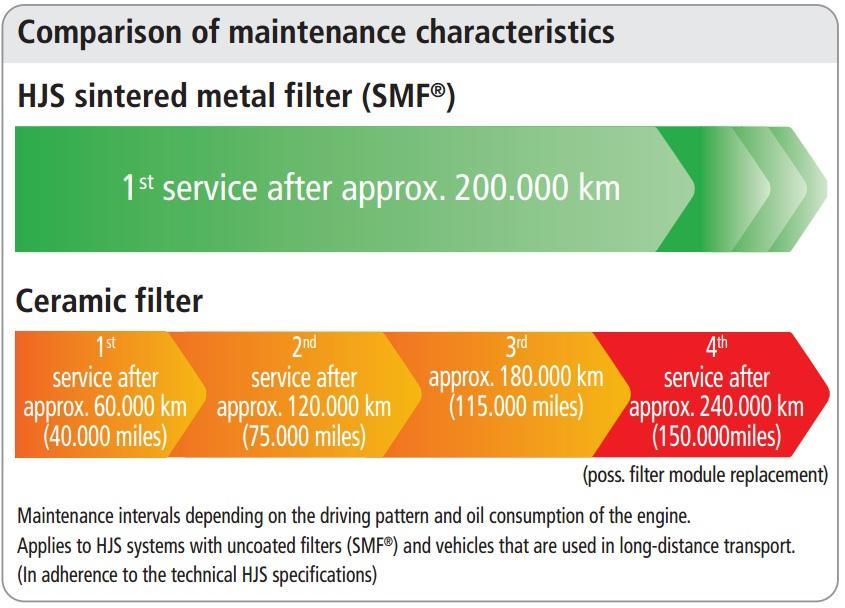

Besides the soot particles, filter systems also remove all other solid particles from the exhaust, mainly ash, engine oils and additives. These residues must be removed from the filter at regular intervals. A display unit for maintenance checks, which is included, monitors the filter continuously and automatically informs the driver when the system needs to be cleaned.

The cleaning intervals are 3-4 times more dilute in comparison with a typical ceramic soot filter of a bus.

When a filter needs to be cleaned, it is quick and easy at the truck’s company’s facilities or a workshop. The filter housing remains mounted on the vehicle. The only removed from the truck is the individual filter segments, which are then cleaned of any residues by means of a high-pressure cleaner of commerce. The filter cleaning can be done as part of routine maintenance of the vehicle.

You can see the video below for how simple it is to clean the filter:

https://www.youtube.com/watch?v=Z1icU7M6VBs

Benefit

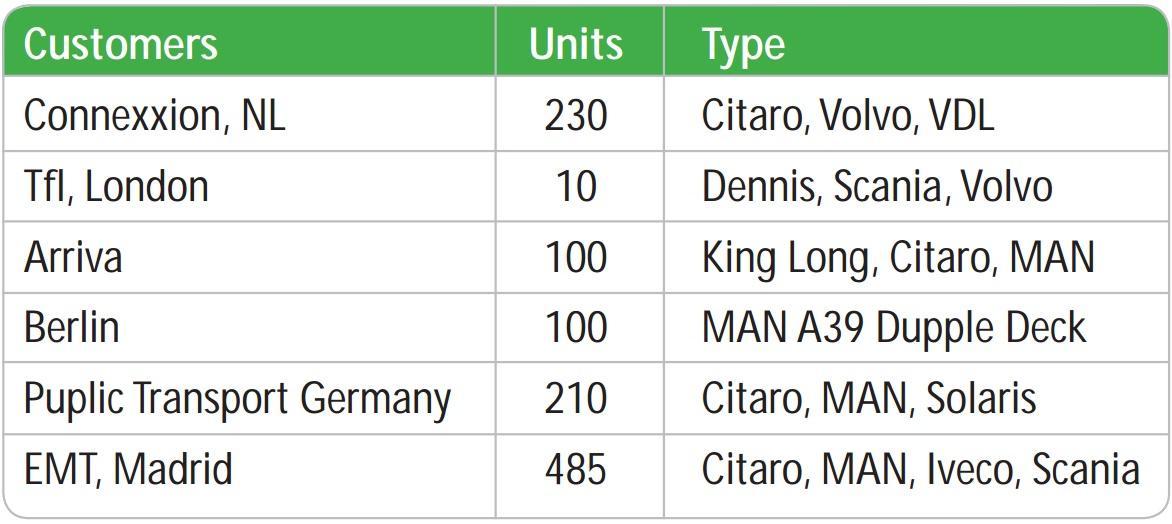

Trust SMF® for retrofitting of vehicles and benefit from the many years of experience in the market. Across Europe, thousands of buses have already successfully installed the particulate filters of HJS. All systems comply with national regulations and are certified in accordance with the applicable licensing provisions as Appendix XXVII in Germany, VERT in Switzerland and approved in Denmark, Italy, the Netherlands and the United Kingdom.

Briefly HJS DPF for buses offer:

- Pioneering technology based on SMF © (sintered metal filter).

- Retrofitting in EURO II and EURO III engines with fast and simple installation.

- Passive regeneration of the filter by CRT© (continuous regeneration technology)

- No replacement is required throughout the lifetime of the vehicle.

- Extremely low cost, rare cleaning intervals and easy service (simple cleaning with water).

- 99% reduction in soot particles even very small particles

- 95% reduction of pollutants, such as CO and HC

- 88% reduction of NOX with SCRT

- Low regeneration temperatures (250 °C-450 °C)

- Review and approval by the German Technical Inspectorate TÜV.

- Best resale value for your vehicle.

- Control unit monitors the operation of the filter and updates the driver (where applicable).